Sarah stared at the three holes in her living room wall, each one slightly larger than the last. The floating shelf she’d bought two months ago was now propped against the radiator, defeated. “It’s just a simple shelf,” she muttered, sweeping up another handful of plaster dust. Sound familiar?

We’ve all been there. That moment when you realize the wall plug you trusted with your favorite books has given up entirely. The shelf crashes down at 2 AM, or worse, slowly sags until everything slides off in a cascade of disappointment.

But here’s what most people don’t know: there’s a simple technique that professional installers use every single day, and it’s not what you’d expect. It’s not about buying expensive plugs or having the right drill. It’s about one crucial step that takes 30 seconds and makes the difference between a shelf that lasts decades and one that fails in weeks.

Why Your Wall Plugs Keep Letting You Down

The truth is, most DIY disasters start before you even pick up the drill. Walk into any hardware store and you’ll see rows of “universal” wall plugs promising to work in any surface. But your wall doesn’t care about marketing promises.

“The wall decides everything,” explains Mark Thompson, a professional fitter with twenty years experience. “Treat plasterboard like brick, and you’re setting yourself up for failure from the start.”

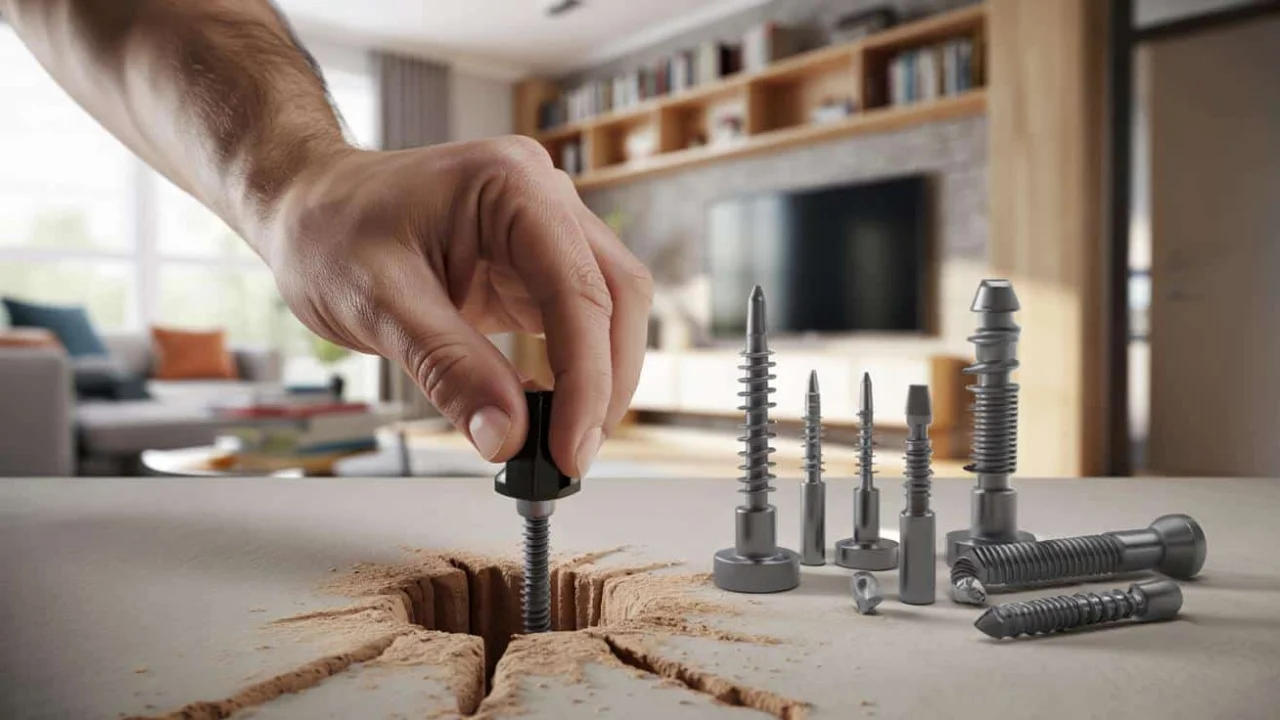

Different wall materials behave completely differently under stress. Plasterboard flexes and can crumble. Brick is solid but can chip. Concrete is strong but unforgiving. Each needs a different approach, and most importantly, a different type of wall plug.

The problem gets worse in older homes where you might have three different wall types in the same room. That beautiful Victorian terrace? It could have original brick, modern plasterboard partitions, and concrete block extensions all within ten feet of each other.

The Secret Technique That Actually Works

Here’s the game-changing trick that professionals swear by: pre-expansion. Most people drill the hole, shove in the plug, and immediately start screwing. But the pros do something different first.

They insert the screw about halfway into the plug before it goes in the wall, then back it out completely. This pre-stretches the plug’s expanding mechanism and creates tiny stress points that help it grip better when you install it properly.

“It sounds almost too simple, but pre-expanding the plug changes everything,” says DIY expert Lisa Chen. “You’re essentially training the plug to expand in exactly the right way.”

The technique works because it removes the initial resistance in the plug’s expansion mechanism. When you drive the screw in for real, the plug expands smoothly and evenly, creating maximum contact with the hole walls.

| Wall Type | Best Plug Type | Drill Bit Size | Pre-expansion Needed |

|---|---|---|---|

| Plasterboard | Toggle/Cavity | Match plug exactly | No (different mechanism) |

| Solid Brick | Expansion | Exactly plug diameter | Yes – essential |

| Concrete | Expansion | Exactly plug diameter | Yes – essential |

| Hollow Block | Special Cavity | Match plug exactly | Depends on design |

Getting Your Wall Type Right Every Time

Before you buy any plugs, you need to know what you’re drilling into. The knuckle test is surprisingly accurate: knock firmly on the wall and listen to the sound.

A solid, dense thud usually means brick, concrete, or stone. A hollow, echoing sound indicates plasterboard or cavity walls. If you hear something in between, you might have hollow blocks or thick plasterboard on battens.

For the ultimate test, drill a small pilot hole with a thin bit. Solid materials create fine, consistent dust. Hollow areas produce different colored dust or suddenly become easy to drill through.

- Expansion plugs: Perfect for solid materials like concrete and brick – they swell outward to grip the hole walls

- Toggle plugs: Essential for plasterboard – they open behind the board to spread the load

- Cavity plugs: Designed for hollow blocks – they grip both the front face and expand into the cavity

- Chemical anchors: The professional choice for maximum holding power in any solid material

“The biggest mistake people make is using expansion plugs in plasterboard,” notes contractor James Wilson. “They just spin and create bigger holes. You need plugs that work with the material, not against it.”

The Real-World Difference This Makes

When you get wall plugs right, the difference is dramatic. Shelves that would normally sag after six months stay perfectly level for years. Heavy mirrors remain secure. Kitchen cabinets don’t gradually pull away from the wall.

But the benefits go beyond just stability. Properly installed wall plugs distribute weight evenly, reducing stress on both the plug and the wall. This means less damage if you ever need to remove them, and fewer repair jobs down the line.

In rental properties, this technique is particularly valuable. Landlords appreciate tenants who don’t damage walls, and you’ll get more of your deposit back. Plus, you won’t have to explain why there are multiple holes where one should have been enough.

The time investment is minimal – maybe an extra minute per plug – but the results last for decades. Professional installers charge premium rates partly because they know these techniques and use them consistently.

“It’s not about having expensive tools or secret products,” explains Chen. “It’s about understanding how each component works and respecting the physics involved.”

FAQs

Do I really need different plugs for different walls?

Yes, absolutely. Universal plugs are a marketing concept – physics doesn’t work that way.

How do I know if my wall plug is properly expanded?

A properly set plug won’t turn when you try to rotate the screw, and there should be slight resistance when inserting the screw.

Can I reuse a hole if the plug fails?

Only if you use a larger plug, or fill the hole completely and start fresh in a new location.

What’s the maximum weight a standard wall plug can hold?

This depends entirely on the wall material and plug type, but expect 20-50kg for properly installed expansion plugs in solid walls.

Why do my plugs work fine initially but fail later?

Usually because the initial expansion wasn’t complete, so the plug gradually works loose under repeated stress.

Should I use wall plugs for very heavy items?

For anything over 30kg, consider chemical anchors or specialist heavy-duty fixings designed for your specific wall type.