Maria stared at the empty tap in her Cape Town apartment, remembering the day three years ago when the city nearly ran out of water completely. She had waited in line for hours just to fill a few containers, watching neighbors argue over who deserved the last drops from a communal standpoint. The memory still made her stomach clench with anxiety.

That same fear now grips millions of people across the globe. From California’s endless droughts to the parched landscapes of Australia, the search for clean drinking water has become humanity’s most urgent puzzle. But deep beneath the North Sea, 600 meters under the crushing darkness of Norwegian waters, engineers are testing a solution that sounds almost too good to be true.

What if we could turn the ocean itself into our ally, using its immense pressure and pristine depths to create fresh water more efficiently than ever before?

The Game-Changing Underwater Desalination Plant

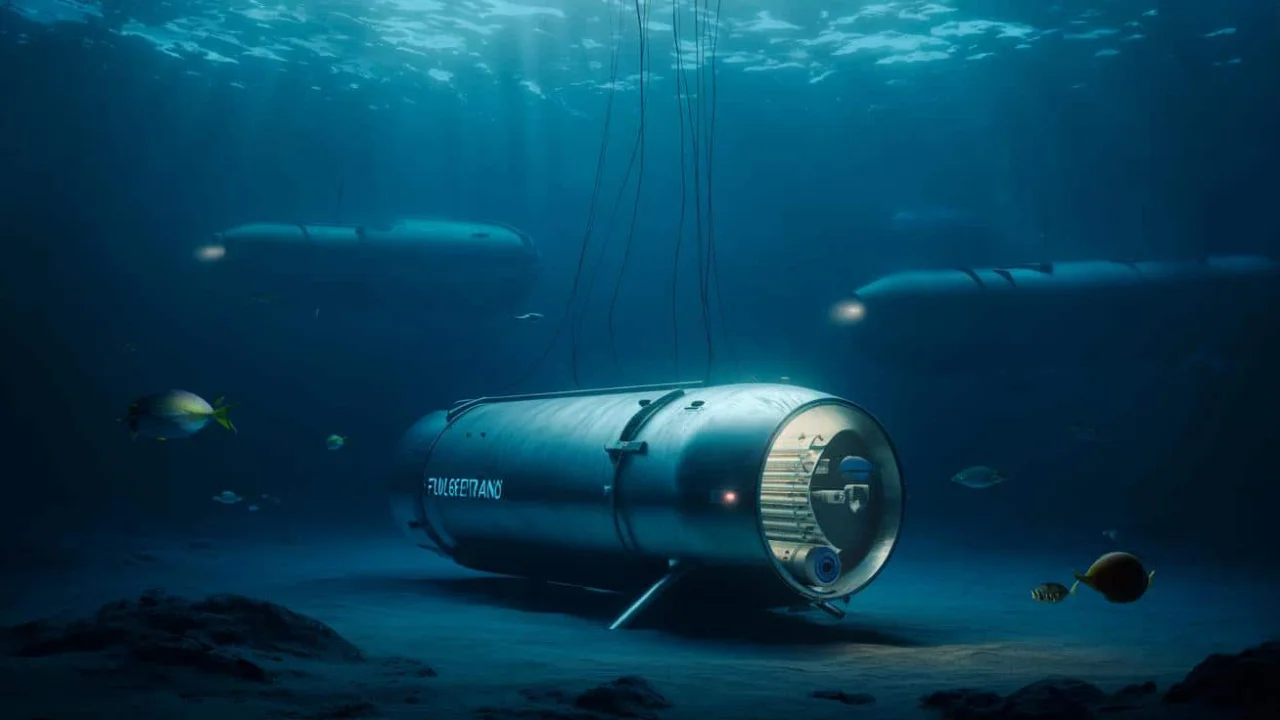

Off the coast of Mongstad, Norway, a metal capsule roughly the size of a small cargo ship is being prepared for the most ambitious water experiment of our time. This is Flocean One, the world’s first fully operational underwater desalination plant, scheduled to begin operations in 2026.

Unlike the massive concrete facilities that dominate coastlines worldwide, this revolutionary system will operate between 300 and 600 meters below the surface. At these crushing depths, where sunlight never penetrates and the pressure could flatten a car, engineers have discovered the perfect conditions for producing fresh water.

“Instead of fighting the sea with pumps, filters and concrete, we’re using the sea itself as our main piece of equipment,” explains Dr. Erik Hansen, a marine engineering consultant who has followed the project closely.

The concept has already earned recognition from TIME magazine, which listed Flocean among its top innovations of 2025. The idea of taking desalination offshore and underwater at industrial scale represents a fundamental shift in how we approach water scarcity.

How Nature Does Half the Heavy Lifting

Traditional desalination plants work like giant pressure cookers. They force seawater through ultra-fine membranes at enormous pressure, leaving salt and impurities behind. Creating that pressure requires massive pumps that guzzle electricity, often generated from fossil fuels.

The underwater desalination plant turns this entire process on its head. At depths of 300-600 meters, the crushing weight of the ocean above provides all the pressure needed to push water through those same membranes—no giant pumps required.

Here’s what makes this system revolutionary:

- Natural ocean pressure replaces energy-intensive industrial pumps

- Fewer mechanical parts mean dramatically lower maintenance costs

- Reduced electricity needs slash both operating expenses and carbon emissions

- Cold, dark water contains fewer biological contaminants than surface water

- Remote location eliminates conflicts with coastal development

Early projections suggest energy consumption could drop by 30-50% compared to conventional shore-based facilities. That’s not just good news for the environment—it could make desalinated water affordable for communities that desperately need it.

“The ocean is doing half our work for us,” notes Sarah Chen, a water technology researcher. “We’re finally learning to work with nature instead of against it.”

| Feature | Traditional Plant | Underwater Plant |

|---|---|---|

| Depth | Shore level | 300-600 meters |

| Pressure source | Electric pumps | Natural ocean pressure |

| Energy reduction | Baseline | 30-50% less |

| Maintenance access | Easy | Challenging but less frequent |

| Environmental impact | High coastal footprint | Minimal surface disruption |

The Deep Ocean’s Hidden Advantages

Beyond pressure, the deep ocean offers unexpected benefits that coastal plants simply can’t match. At 600 meters down, the water is cold, dark, and remarkably clean compared to the biological soup that exists near shorelines.

Coastal desalination facilities constantly battle algae blooms, marine growth, and seasonal contamination that can clog their systems. The underwater desalination plant sidesteps these problems entirely by operating in water that’s naturally filtered by the ocean’s depths.

“It’s like the difference between drawing water from a busy harbor versus a pristine mountain lake,” explains Dr. Hansen. “The cleaner the input, the more efficient the entire system becomes.”

This biological advantage translates into real operational benefits. Less pre-treatment means fewer chemicals, less maintenance, and more consistent output. The system can run longer between cleaning cycles, reducing both costs and downtime.

What This Could Mean for Water-Scarce Regions

If successful, underwater desalination plants could transform how coastal nations approach water security. Countries from Australia to South Africa, from California to the Middle East, are watching this Norwegian experiment with intense interest.

The implications extend far beyond just producing more fresh water. These systems could be deployed in locations where traditional plants would be impossible—near environmentally sensitive coastlines, in rough seas, or in politically disputed waters.

For island nations particularly, the technology offers hope for energy-efficient water independence. Small island states in the Pacific and Caribbean, which currently rely on expensive, fuel-hungry desalination systems, could dramatically reduce their water production costs.

“This could be the breakthrough that makes desalinated water accessible to communities that have never been able to afford it,” says Maria Rodriguez, a water policy analyst. “We’re talking about changing lives on a massive scale.”

The modular design also means these plants could be mass-produced and deployed relatively quickly compared to building massive coastal facilities. A country facing a water crisis wouldn’t need to spend years constructing infrastructure—they could potentially lease or purchase a system and have it operational within months.

The Challenges Still Ahead

Operating any industrial facility 600 meters underwater presents obvious challenges. Maintenance requires specialized equipment and trained divers or remotely operated vehicles. Emergency repairs become complex logistical operations rather than simple service calls.

The initial costs are also substantial. While operating expenses may be lower, the engineering required to build and deploy these systems isn’t cheap. Early adopters will need to see the long-term savings potential to justify the investment.

Weather conditions pose another consideration. While the deep ocean is generally calmer than the surface, severe storms can still affect operations. The system needs robust engineering to handle everything from routine operations to emergency shutdowns.

Despite these hurdles, the potential rewards are driving significant interest from both private investors and government agencies worldwide.

Looking Toward 2026 and Beyond

As Flocean One prepares for deployment, water experts around the globe are holding their breath. The success or failure of this first industrial-scale underwater desalination plant could determine whether this technology becomes a game-changer or remains an interesting experiment.

If the Norwegian test succeeds, we could see similar systems deployed in water-stressed regions within the next decade. The technology could scale up to massive installations or down to smaller units serving individual communities.

For people like Maria in Cape Town, who still remember the terror of taps running dry, this underwater innovation represents something more than just engineering advancement—it’s hope that future water crises might become problems of the past rather than threats of the future.

FAQs

How deep underwater will these desalination plants operate?

The plants will operate between 300 and 600 meters below the surface, where ocean pressure is naturally high enough to power the desalination process.

How much energy could underwater desalination save compared to traditional plants?

Early projections suggest energy consumption could be reduced by 30-50% compared to conventional shore-based desalination facilities.

When will the first underwater desalination plant start working?

Flocean One, the world’s first fully operational underwater desalination plant, is scheduled to begin service in 2026 off the coast of Norway.

What makes underwater desalination more efficient than coastal plants?

The natural ocean pressure eliminates the need for energy-intensive pumps, while the cold, clean deep water requires less pre-treatment and maintenance.

Could underwater desalination plants be used in other countries?

Yes, the technology could potentially be deployed in any coastal region with sufficient depth, making it particularly valuable for water-scarce island nations and coastal communities.

What are the main challenges of operating desalination plants underwater?

The primary challenges include complex maintenance procedures, higher initial costs, and the need for specialized equipment to service systems at depth.