Maria watched her car’s transmission fail for the third time in two years, steam rising from under the hood as she pulled over on the highway. “There has to be a better way,” she muttered, thinking about all those metal gears grinding against each other inside her engine. Little did she know, hundreds of miles away in a New York laboratory, scientists were asking the exact same question.

What if gears didn’t need to touch at all? What if motion could be transmitted through liquid instead of metal teeth clicking together? It sounds like science fiction, but researchers have made it reality.

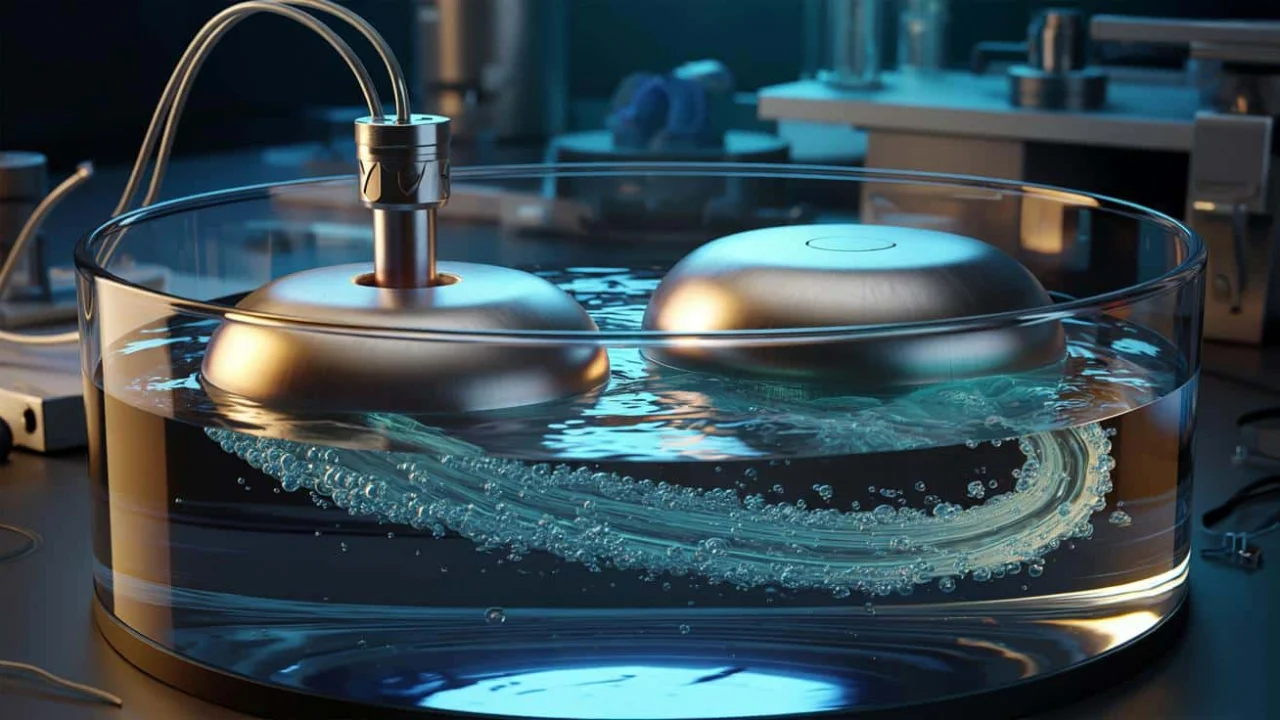

In that quiet lab, two smooth metal cylinders sit in a clear bath of liquid, spinning silently as one transfers power to the other without ever making contact. These liquid gears could change everything we know about mechanical systems.

Why Traditional Gears Keep Breaking Down

Every time you shift your car, open a can, or watch a clock tick, you’re witnessing thousands of years of gear technology at work. But here’s the problem: those metal teeth are constantly wearing each other down.

Think about it. Traditional gears work by having their teeth mesh together, creating friction and heat every single time they turn. Over time, this causes chips, cracks, and complete failure. That’s why your car needs regular transmission fluid changes and why industrial machinery requires constant maintenance.

“The fundamental issue with conventional gears is that they rely on physical contact,” explains Dr. James Peterson, a mechanical engineering professor. “Every contact point is a potential failure point.”

The researchers at New York University started with a simple but revolutionary question: do gear elements really need to touch each other to transmit motion? Their answer has stunned the engineering world.

How These Liquid Gears Actually Work

The liquid gear system is surprisingly elegant in its simplicity. Here’s what makes it so remarkable:

- Two smooth cylinders – No teeth, no complex shapes, just basic metal cylinders

- Specially formulated liquid – A mixture of water and glycerol that can be adjusted for different viscosities

- Fluid dynamics – The rotating cylinder drags liquid with it, creating controlled flow patterns

- Motion transfer – These swirling flows cause the second cylinder to rotate automatically

When the motor-driven cylinder starts spinning, it creates what engineers call “viscous coupling.” The liquid sticks to the cylinder’s surface and gets dragged along, forming circular currents that push against the second cylinder.

“It’s like having an invisible connection between the two parts,” says Dr. Sarah Chen, who studies fluid mechanics. “The liquid becomes the gear teeth, but without any of the wear and tear.”

The beauty lies in the tunability. By adjusting the water-to-glycerol ratio, researchers can control how much torque gets transmitted and how fast the second cylinder spins.

| Liquid Composition | Viscosity Level | Torque Transmission | Speed Ratio |

|---|---|---|---|

| 90% Water, 10% Glycerol | Low | Moderate | 1:1.2 |

| 50% Water, 50% Glycerol | Medium | High | 1:1.5 |

| 20% Water, 80% Glycerol | High | Maximum | 1:2.1 |

What This Means for Your Daily Life

You might think liquid gears sound too futuristic to matter right now, but they could solve problems you deal with every day. Remember Maria’s transmission troubles? Liquid gear systems could eliminate most of those headaches.

Cars with liquid transmissions would need far less maintenance. No more grinding gears, no more metal shavings contaminating your transmission fluid, and potentially much longer lifespans for the entire system.

But the applications go way beyond automobiles:

- Robotics – Smoother, quieter robotic joints that last longer

- Wind turbines – Reduced maintenance in those hard-to-reach places

- Manufacturing equipment – Less downtime for gear replacement

- Medical devices – Precise, quiet operation for surgical robots

“We’re looking at a technology that could revolutionize any industry that relies on mechanical motion,” notes Dr. Michael Rodriguez, an automotive engineer. “The potential cost savings from reduced maintenance alone are enormous.”

The aerospace industry is particularly excited. Imagine aircraft engines with fewer moving parts to fail, or spacecraft mechanisms that don’t degrade in the harsh environment of space.

The Challenges Nobody’s Talking About

Before you get too excited about liquid gears, there are some real hurdles to overcome. The system works beautifully in laboratory conditions, but the real world is messier.

Temperature changes affect liquid viscosity dramatically. Your liquid gear system might work perfectly at room temperature but fail completely when it’s freezing outside or blazingly hot under the hood of a car.

Sealing is another major challenge. Traditional gears can handle some leakage, but liquid gear systems need perfect containment. One small leak and your entire transmission could fail catastrophically.

“The engineering challenges are significant,” admits Dr. Peterson. “But remember, the first computers filled entire rooms. Technology has a way of becoming more practical over time.”

There’s also the question of power efficiency. While liquid gears eliminate friction between gear teeth, they create their own type of internal friction within the fluid itself. The researchers are still working to optimize this balance.

When Will We See Liquid Gears Everywhere?

Don’t expect to buy a liquid gear transmission next year, but the timeline isn’t as far off as you might think. The researchers believe practical applications could emerge within the next decade.

The first commercial uses will likely be in specialized applications where the benefits clearly outweigh the challenges. Think high-end robotics, precision medical equipment, or aerospace components where maintenance costs are already extremely high.

“We’re not trying to replace every gear system immediately,” explains Dr. Chen. “We’re starting with applications where smooth, quiet operation is worth the added complexity.”

Consumer applications will follow as the technology matures and costs come down. Your future car might not have liquid gears in the main transmission but could use them in power steering, air conditioning, or other auxiliary systems.

FAQs

How do liquid gears work without physical contact?

They use the viscosity of specially formulated liquids to transfer rotational motion through fluid dynamics, similar to how a spoon stirring honey causes the entire jar to move.

Are liquid gears more efficient than traditional gears?

They eliminate gear tooth friction but create fluid friction instead. The overall efficiency depends on the specific application and liquid formulation used.

What happens if the liquid leaks out?

The system would fail to transmit motion, which is why perfect sealing is crucial for practical applications of liquid gear technology.

Can liquid gears handle high torque applications?

Yes, by adjusting the liquid’s viscosity and the cylinder design, researchers can tune the system for different torque requirements.

Will liquid gears replace all traditional gears?

No, they’ll likely be used in specific applications where their advantages (smooth operation, reduced wear) outweigh their challenges (sealing, temperature sensitivity).

When will liquid gears be available commercially?

Specialized applications could see liquid gears within 5-10 years, while consumer applications will likely take longer as the technology matures.