Maria Santos had been driving mining trucks for fifteen years when her company offered her a promotion to work at a new high-altitude site. The pay was incredible—triple her usual salary. But there was a catch: the mine sat so high in the mountains that workers needed oxygen masks just to walk around, and medical evacuations could take hours in good weather.

She turned it down. “I have kids to think about,” she told her supervisor. “What’s the point of great money if you might not make it home?”

Maria’s concern reflects a reality that mining companies worldwide are grappling with: some deposits are simply too dangerous for human workers. But in China’s remote Kunlun mountains, engineers have found a different solution—one that doesn’t require risking human lives at all.

When Mountains Become Mining’s Final Frontier

The Huoshaoyun mine represents everything that makes modern resource extraction both incredibly lucrative and impossibly dangerous. Perched at 5,600 meters above sea level in China’s disputed Aksai Chin region, it sits higher than most commercial aircraft fly.

At that altitude, every breath contains about half the oxygen you’d get at sea level. Temperatures regularly plummet to -20°C and below. Workers would need constant medical monitoring, specialized equipment just to survive, and emergency evacuation procedures that might not work when weather turns bad.

“The human body simply wasn’t designed to do heavy labor at those altitudes,” explains Dr. James Mitchell, a specialist in high-altitude medicine. “Even acclimatized workers face significant health risks during extended shifts.”

But underneath that hostile frozen landscape lies treasure worth fighting for—over 21 million tonnes of lead and zinc ore, valued at approximately €45 billion. That makes Huoshaoyun the seventh-largest lead-zinc deposit globally, and it’s far from fully tapped.

For Chinese mining company Guanghui Energy, the math was simple: find a way to extract the ore without putting human lives at risk, or leave billions of euros buried in the permafrost.

Autonomous Trucks Mining the Impossible

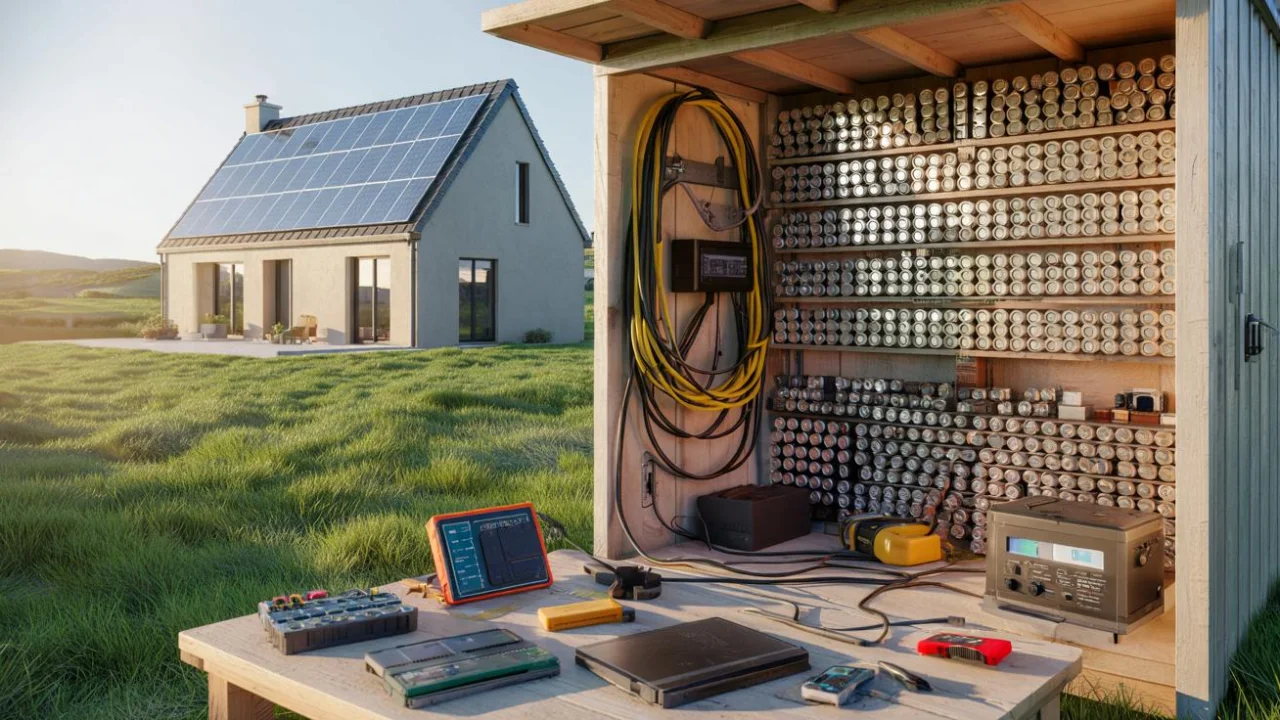

China’s solution involves deploying a fleet of autonomous trucks mining operations that can handle the brutal conditions where humans cannot. These aren’t simple remote-controlled vehicles—they’re sophisticated machines that think, adapt, and make decisions in real-time.

Each truck carries multiple sensor systems working together:

- Advanced radar systems that penetrate snow and dust

- LiDAR technology creating 3D maps of surroundings

- Multiple high-resolution cameras with infrared capabilities

- On-board computing systems processing thousands of data points per second

- GPS systems enhanced for extreme altitude operations

“These autonomous trucks mining systems don’t just follow pre-programmed routes,” notes Zhang Wei, a robotics engineer familiar with the project. “They actively interpret their environment, adjusting to changing weather, obstacles, or equipment failures.”

The vehicles continuously scan their surroundings, identifying safe paths through terrain that shifts with weather and mining operations. When sensors detect an obstacle—whether it’s falling rocks, equipment, or changing road conditions—the trucks calculate new routes automatically.

| Capability | Human Driver at Altitude | Autonomous System |

|---|---|---|

| Operating Hours | 6-8 hours max (health limits) | 24/7 operation possible |

| Reaction Time | Slower due to altitude effects | Millisecond response |

| Weather Tolerance | Limited by safety concerns | Operates in most conditions |

| Medical Risk | Constant altitude sickness threat | No medical considerations |

What This Means Beyond One Chinese Mine

The success of autonomous trucks mining at Huoshaoyun could reshape how we think about resource extraction in hostile environments. Mining companies worldwide are watching this experiment closely, because similar challenges exist everywhere from Arctic diamond mines to underwater operations.

“If China can make this work economically, it opens up deposits that were previously considered impossible to develop,” explains Sarah Chen, a mining industry analyst. “We’re talking about trillions of euros in untapped resources globally.”

The technology could revolutionize mining in several key areas:

- Deep ocean mining where human presence is impossible

- Arctic operations with extreme cold and isolation

- Desert mines with dangerous heat and sandstorm conditions

- Radioactive sites where human exposure must be minimized

- Conflict zones too dangerous for regular operations

But the implications extend beyond just mining. The same autonomous systems could transform disaster response, military logistics, and cargo transport in dangerous areas.

The Human Cost of Going Automated

While autonomous trucks mining operations solve the safety problem, they create new challenges for workers and communities that depend on mining jobs. Traditional mining employs millions of people worldwide, from drivers and equipment operators to maintenance crews and support staff.

“Every autonomous truck potentially replaces several human jobs,” acknowledges mining economist Robert Kim. “Companies need to think carefully about how they manage this transition.”

Some mining companies are retraining workers to operate and maintain autonomous fleets rather than simply eliminating positions. The technology requires sophisticated technical support, remote monitoring, and regular maintenance that still needs human expertise.

At Huoshaoyun, the approach appears to be creating new types of jobs rather than simply cutting employment. Workers now monitor multiple vehicles from control centers, analyze sensor data, and coordinate complex logistics operations from safe locations.

Looking Ahead: The Future of Extreme Mining

The success at Huoshaoyun represents just the beginning of autonomous mining technology. Companies are already developing more advanced systems that can handle entire mining operations with minimal human oversight.

Future autonomous trucks mining systems might include:

- Self-repair capabilities using AI diagnostics

- Swarm coordination allowing multiple vehicles to work together

- Predictive maintenance preventing breakdowns before they occur

- Enhanced AI that learns and adapts to specific mining sites

“We’re moving toward a future where the most dangerous mining jobs are handled entirely by machines,” predicts technology analyst Laura Martinez. “The question isn’t whether this will happen, but how quickly it spreads to other industries.”

As China continues testing its autonomous fleet at 5,600 meters above sea level, the rest of the world is taking notes. The success or failure of this €45 billion experiment could determine whether autonomous trucks mining becomes the new standard for extreme resource extraction—or remains an expensive experiment in the world’s most hostile places.

FAQs

How do autonomous mining trucks navigate in extreme weather conditions?

They use multiple sensor systems including radar and infrared cameras that work in snow, dust, and low visibility, while AI systems process environmental data to adjust routes in real-time.

What happens if an autonomous truck breaks down in such a remote location?

The vehicles have self-diagnostic systems that predict failures, and backup trucks can be dispatched remotely, though severe breakdowns still require human technicians with specialized high-altitude equipment.

Are these autonomous trucks completely driverless or remotely controlled?

They operate semi-autonomously, making most decisions independently but with human supervisors monitoring from control centers who can intervene when necessary.

How much does it cost to deploy autonomous trucks versus human-operated ones at extreme altitudes?

While initial technology costs are higher, companies save on medical support, safety infrastructure, and worker insurance, making autonomous systems more economical for extreme environments.

Could this technology be used in regular mining operations at normal altitudes?

Yes, and many mining companies are already testing autonomous vehicles in conventional mines to improve safety and efficiency, even where human operation is possible.

What safety measures prevent autonomous trucks from causing accidents?

Multiple redundant sensor systems, constant communication with control centers, and fail-safe programming that stops vehicles when sensors detect potential hazards or system malfunctions.